Driving Efficiency and Cost Effectiveness: The Essential Role of Filtration in Utility Applications

Share

In the dynamic landscape of industrial manufacturing, where operational efficiency and cost management are pivotal, filtration solutions emerge as critical assets across utility applications. From water treatment to process fluid filtration, these systems are indispensable for optimizing productivity and minimizing operational expenditures.

The Economic Impact of Filtration in Utility Applications

Filtration systems play a crucial role in industrial utility applications for several compelling reasons:

- Enhanced Operational Efficiency: By maintaining clean process fluids and reducing contaminants, filtration systems contribute significantly to equipment reliability and operational uptime, ultimately enhancing overall efficiency.

- Cost Savings: Effective filtration prolongs the lifespan of equipment and reduces the frequency of maintenance cycles, thereby lowering operational costs and improving budget predictability.

- Compliance Assurance: Meeting stringent regulatory standards for water quality and environmental sustainability is imperative. Filtration systems ensure compliance, mitigating risks associated with non-compliance penalties.

Introducing Polypropylene (PP) Melt Blown Filter Cartridges

PP Melt Blown Filter Cartridges by PARSWOOD™️ are engineered to deliver exceptional cost efficiency and performance:

- Cost-Effective Design: These cartridges feature a three-layer structure composed of thermally bonded polypropylene fibers, optimizing filtration efficiency and durability while minimizing operational costs.

- Versatile Applications: Suitable for diverse utility applications including R.O. pre-filtration, process water treatment, and industrial wastewater management, these cartridges offer flexibility and reliability in challenging industrial environments.

- Economic Benefits: By reducing pressure drop and enhancing filtration performance, PP Melt Blown cartridges contribute to energy savings and operational cost reduction, supporting sustainable business practices.

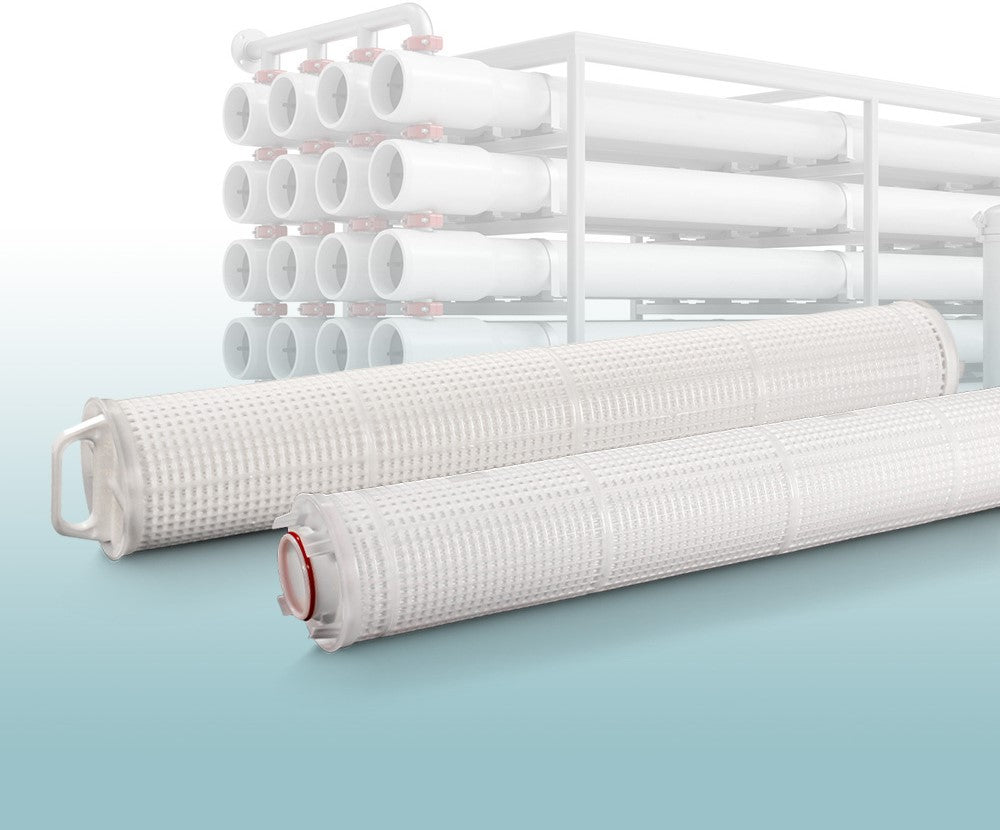

High Flow Cartridges: Optimizing Efficiency and Maintenance Costs

PARSWOOD™️’s High Flow Cartridges are designed to maximize cost-effectiveness and utility performance:

- Superior Filtration Capacity: Featuring a large diameter and multiple pleated layers, these cartridges provide higher efficiency and extended service life compared to conventional alternatives, reducing downtime and labor costs.

- Seamless Integration: Engineered to retrofit seamlessly into existing bag filter housings, High Flow Cartridges streamline installation and maintenance processes, minimizing operational disruptions and expenses.

- Durable Construction: Constructed from 100% polypropylene components, these cartridges ensure chemical compatibility and reliability in diverse industrial applications, enhancing long-term cost savings through reduced maintenance and replacement costs.

Conclusion

Investing in advanced filtration solutions such as Polypropylene Melt Blown and High Flow Cartridges from PARSWOOD™️ not only optimizes operational efficiency but also delivers significant cost savings across utility applications in industrial manufacturing. By enhancing filtration processes and ensuring regulatory compliance, these solutions empower businesses to achieve sustainable growth and competitive advantage in their respective industries.

For industrial professionals seeking to enhance efficiency and reduce operational costs without compromising on performance, PARSWOOD™️’s innovative filtration solutions offer a reliable pathway. Explore how these solutions can elevate your operations by contacting our sales team today.